Nexys 2 Reference Manual

The Nexys 2 is now retired and no longer for sale in our store. We recommend the Nexys A7 FPGA as an alternative.

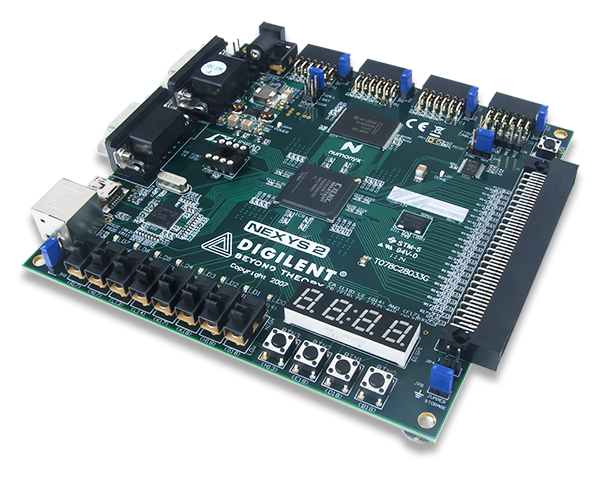

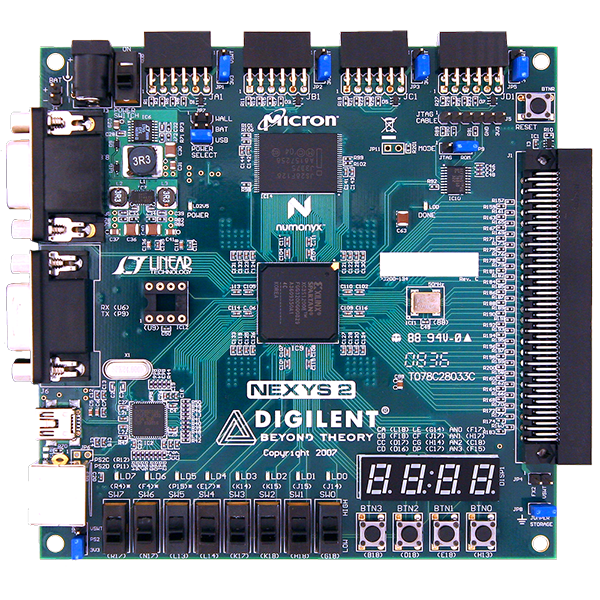

Nexys2 circuit board is a complete, ready-to-use circuit development platform based on a Xilinx Spartan 3E FPGA. Its on-board high-speed USB2 port, 16Mbytes of RAM and ROM, and several I/O devices and ports make it an ideal platform for digital systems of all kinds, including embedded processor systems based on Xilinx’s MicroBlaze. The USB2 port provides board power and a programming interface, so the Nexys2 board can be used with a notebook computer to create a truly portable design station.

Download This Reference Manual

Features

- 500K-gate Xilinx Spartan 3E FPGA

- USB2-based FPGA configuration and high-speed data transfers (using the free Adept Suite Software)

- USB-powered (batteries and/or wall-plug can also be used)

- 16MB of Micron PSDRAM &16MB of Intel StrataFlash ROM

- Xilinx Platform Flash for nonvolatile FPGA configurations

- Efficient switch-mode power supplies (good for battery powered applications)

- 50MHz oscillator plus socket for second oscillator

- 60 FPGA I/O’s routed to expansion connectors (one high-speed Hirose FX2 connector and four 6-pin headers)

- 8 LEDs, 4-digit 7-seg display, 4 buttons, 8 slide switches

- Ships in a plastic carry case with USB cable

The Nexys2 brings leading technologies to a platform that anyone can use to gain digital design experience. It can host countless FPGA-based digital systems, and designs can easily grow beyond the board using any or all of the five expansion connectors. Four 12-pin Peripheral Module (Pmod) connectors can accommodate up to eight low-cost Pmods to add features like motor control, A/D and D/A conversion, audio circuits, and a host of sensor and actuator interfaces. All user-accessible signals on the Nexys2 board are ESD and short-circuit protected, ensuring a long operating life in any environment.

The Nexys2 board is fully compatible with all versions of the Xilinx ISE tools, including the free WebPack. Now anyone can build real digital systems for less than the price of a textbook.

Power Supplies

The Nexys2 board input power input bus can be driven from a USB cable, from a 5VDC-15VDC, center positive, 2.1mm wall-plug supply, or from a battery pack. A shorting block loaded on the “power select” jumper selects the power source. The USB circuitry is always powered from the USB cable – if no USB cable is attached, the USB circuitry is left unpowered.

| Nexys2 Power Supplies | ||

| Supply | Device | Amps (max/typ) |

| 3.3V main | IC6: LTC1765 | 3A/100mA |

| 2.5V FPGA | IC7: LTC3417 | 1.4A/50mA |

| 1.2V FPGA | IC7: LTC3417 | 1.4A/200mA |

| 1.8V SRAM | IC8: LTC1844 | 150mA/90mA |

| 3.3V USB | IC5: LTC1844 | 150mA/60mA |

The input power bus drives a 3.3V voltage regulator that supplies all required board current. Some devices require 2.5V, 1.8V, and 1.2V supplies in addition to the main 3.3V supply, and these additional supplies are created by regulators that take their input from the main 3.3V supply. The primary supplies are generated by highly efficient switching regulators from Linear Technology. These regulators not only use USB power efficiently, they also allow the Nexys2 to run from battery packs for extended periods.

Total board current depends on the FPGA configuration, clock frequency, and external connections. In test circuits with roughly 20K gates routed, a 50MHz clock source, and all LEDs illuminated, about 200mA of current is drawn from the 1.2V supply, 50mA from the 2.5V supply, and 100mA from the 3.3V supply. Required current will increase if larger circuits are configured in the FPGA, and if peripheral boards are attached. The table above summarizes the power supply parameters.

The Nexys2 board can also receive power from (or deliver power to) a peripheral board connected to a Pmod connector or to the large 100-pin expansion connector. Jumpers near the Pmod connectors and large expansion connector (JP1 – JP5) can connect the Nexys2’s input power bus to the connector’s power pins. The Pmod jumpers can be used to route either the input power bus or regulated 3.3V to the Pmod power pins, while the expansion connector jumper can only make or break a connection with the input power bus.

The Nexys2 board can also receive power from (or deliver power to) a peripheral board connected to a Pmod connector or to the large 100-pin expansion connector. Jumpers near the Pmod connectors and large expansion connector (JP1 – JP5) can connect the Nexys2’s input power bus to the connector’s power pins. The Pmod jumpers can be used to route either the input power bus or regulated 3.3V to the Pmod power pins, while the expansion connector jumper can only make or break a connection with the input power bus.

USB power is supplied to the USB circuitry directly, but to the rest of the board through an electronic switch (Q1 in the Nexys2 schematic). The on-board USB controller turns on switch Q1 only after informing the host PC that more than 100mA will be drawn through the USB cable (as required by the USB specification). A USB host can supply only 500mA of current at 5VDC. When using USB power, care must be taken to ensure the Nexys2 board and any attached peripheral boards do not draw more than 500mA, or damage to the host may result. The Nexys2 board typically consumes about 300mA of USB current, leaving about 200mA for peripheral boards. If peripheral boards require more current than the USB cable can supply, an external power supply should be used.

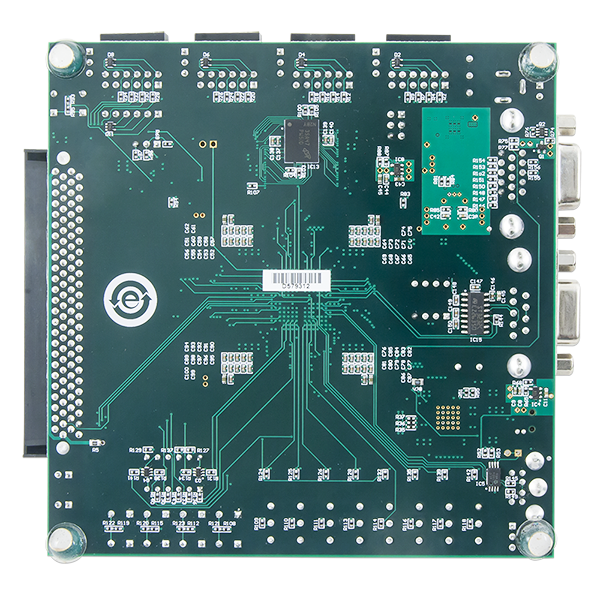

The Nexys2 board uses a six layer PCB, with the inner layers dedicated to VCC and GND planes. The FPGA and the other ICs on the board all have a large complement of bypass capacitors placed as close as possible to each VCC pin. The power supply routing and bypass capacitors result in a very clean, stable, and low-noise power supply.

FPGA and Platform Flash Configuration

The FPGA on the Nexys2 board must be configured (or programmed) by the user before it can perform any functions. During configuration, a “bit” file is transferred into memory cells within the FPGA to define the logical functions and circuit interconnects. The free ISE/WebPack CAD software from Xilinx can be used to create bit files from VHDL, Verilog, or schematic-based source files.

The FPGA can be programmed in two ways: directly from a PC using the on-board USB port, and from an on-board Platform Flash ROM (the Flash ROM is also user-programmable via the USB port). A jumper on the Nexys2 board determines which source (PC or ROM) the FPGA will use to load its configuration. The FPGA will automatically load a configuration from the Platform Flash ROM at power-on if the configuration Mode jumper is set to “Master serial”. If the Mode jumper is set to “JTAG”, the FPGA will await programming from the PC (via the USB cable).

Digilent’s freely available PC-based Adept software can be used to configure the FPGA and Platform Flash with any suitable file stored on the computer. Adept uses the USB cable to transfer a selected bit file from the PC to the FPGA or Platform Flash ROM. After the FPGA is configured, it will remain so until it is reset by a power-cycle event or by the FPGA reset button (BTNR) being pressed. The Platform Flash ROM will retain a bit file until it is reprogrammed, regardless of power-cycle events.

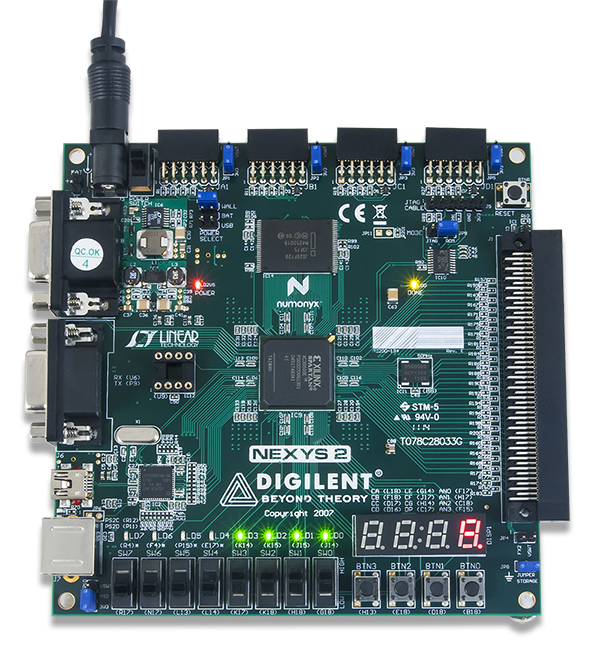

To program the Nexys2 board using Adept, attach the USB cable to the board (if USB power will not be used, attach a suitable power supply to the power jack or battery connector on the board, and set the power switch to “wall” or “bat”). Start the Adept software, and wait for the FPGA and the Platform Flash ROM to be recognized. Use the browse function to associate the desired .bit file with the FPGA, and/or the desired .mcs file with the Platform Flash ROM. Right-click on the device to be programmed, and select the “program” function. The configuration file will be sent to the FPGA or Platform Flash, and the software will indicate whether programming was successful. The configuration “done” LED will illuminate after the FPGA has been successfully configured. For further information on using Adept, please see the Adept documentation available at the Digilent website.

The configuration “done” LED will illuminate after the FPGA has been successfully configured. For further information on using Adept, please see the Adept documentation available at the Digilent website.

The Nexys2 board can also be programmed using Xilinx’s iMPACT software by connecting a suitable programming cable to the JTAG header. Digilent’s JTAG3 cable or any other Xilinx cable may be used.

A demonstration configuration is loaded into the Platform Flash on the Nexys2 board during manufacturing. That configuration, also available on the Digilent webpage, can be used to check all of the devices and circuits on the Nexys2 board.

Clocks

The Nexys2 board includes a 50MHz oscillator and a socket for a second oscillator. Clock signals from the oscillators connect to global clock input pins on the FPGA so they can drive the clock synthesizer blocks available in FPGA. The clock synthesizers (called DLLs, or delay locked loops) provide clock management capabilities that include doubling or quadrupling the input frequency, dividing the input frequency by any integer multiple, and defining precise phase and delay relationships between various clock signals.

User I/O

The Nexys2 board includes several input devices, output devices, and data ports, allowing many designs to be implemented without the need for any other components.

Inputs: Slide Switches and Pushbuttons

Four pushbuttons and eight slide switches are provided for circuit inputs. Pushbutton inputs are normally low, and they are driven high only when the pushbutton is pressed. Slide switches generate constant high or low inputs depending on their position. Pushbutton and slide switch inputs use a series resistor for protection against short circuits (a short circuit would occur if an FPGA pin assigned to a pushbutton or slide switch was inadvertently defined as an output).

Output LEDs

Eight LEDs are provided for circuit outputs. LED anodes are driven from the FPGA via 390-ohm resistors, so a logic ‘1’ output will illuminate them with 3-4ma of drive current. A ninth LED is provided as a power-on LED, and a tenth LED indicates FPGA programming status. Note that LEDs 4-7 have different pin assignments due to pinout differences between the -500 and the -1200 die.

Outputs: Seven-Segment Display

The Nexys2 board contains a four-digit common anode seven-segment LED display. Each of the four digits is composed of seven segments arranged in a “figure 8” pattern, with an LED embedded in each segment. Segment LEDs can be individually illuminated, so any one of 128 patterns can be displayed on a digit by illuminating certain LED segments and leaving the others dark. Of these 128 possible patterns, the ten corresponding to the decimal digits are the most useful.

The anodes of the seven LEDs forming each digit are tied together into one “common anode” circuit node, but the LED cathodes remain separate. The common anode signals are available as four “digit enable” input signals to the 4-digit display. The cathodes of similar segments on all four displays are connected into seven circuit nodes labeled CA through CG (so, for example, the four “D” cathodes from the four digits are grouped together into a single circuit node called “CD”). These seven cathode signals are available as inputs to the 4-digit display. This signal connection scheme creates a multiplexed display, where the cathode signals are common to all digits but they can only illuminate the segments of the digit whose corresponding anode signal is asserted.

A scanning display controller circuit can be used to show a four-digit number on this display. This circuit drives the anode signals and corresponding cathode patterns of each digit in a repeating, continuous succession, at an update rate that is faster than the human eye can detect. Each digit is illuminated just one-quarter of the time, but because the eye cannot perceive the darkening of a digit before it is illuminated again, the digit appears continuously illuminated. If the update or “refresh” rate is slowed to around 45 hertz, most people will begin to see the display flicker.

A scanning display controller circuit can be used to show a four-digit number on this display. This circuit drives the anode signals and corresponding cathode patterns of each digit in a repeating, continuous succession, at an update rate that is faster than the human eye can detect. Each digit is illuminated just one-quarter of the time, but because the eye cannot perceive the darkening of a digit before it is illuminated again, the digit appears continuously illuminated. If the update or “refresh” rate is slowed to around 45 hertz, most people will begin to see the display flicker.

In order for each of the four digits to appear bright and continuously illuminated, all four digits should be driven once every 1 to 16ms, for a refresh frequency of 1KHz to 60Hz. For example, in a 60Hz refresh scheme, the entire display would be refreshed once every 16ms, and each digit would be illuminated for ¼ of the refresh cycle, or 4ms. The controller must drive the cathodes with the correct pattern when the corresponding anode signal is driven. To illustrate the process, if AN0 is asserted while CB and CC are asserted, then a “1” will be displayed in digit position 1. Then, if AN1 is asserted while CA, CB and CC are asserted, then a “7” will be displayed in digit position 2. If AN0 and CB, CC are driven for 4ms, and then A1 and CA, CB, CC are driven for 4ms in an endless succession, the display will show “17” in the first two digits. An example timing diagram for a four-digit controller is provided.

To illustrate the process, if AN0 is asserted while CB and CC are asserted, then a “1” will be displayed in digit position 1. Then, if AN1 is asserted while CA, CB and CC are asserted, then a “7” will be displayed in digit position 2. If AN0 and CB, CC are driven for 4ms, and then A1 and CA, CB, CC are driven for 4ms in an endless succession, the display will show “17” in the first two digits. An example timing diagram for a four-digit controller is provided.

USB Port

The Nexys2 includes a high-speed USB2 port based on a Cypress CY7C68013A USB controller. The USB port can be used to program the on-board Xilinx devices, to perform user-data transfers at up to 38Mbytes/sec, and to provide power to the board. Programming is accomplished with Digilent’s free Adept Suite Software. User data transfers can also be accomplished using the Adept software, or custom user software can be written using Digilent’s public API’s to access the Nexys2 USB connection. Information on using Adept and/or the public API’s to transfer data can be found on the Digilent website.

The USB port can also provide power to the Nexys2 board if the power select jumper is set to “USB”. The USB specification requires that attached devices draw no more than 100mA until they have requested more current, after which up to 500mA may be drawn. When first attached to a USB host, the Nexys2 board requests 500mA, and then activates a transistor switch to connect the USB cable voltage to the main input power bus. The Nexys2 board typically draws around 300mA from the USB cable, and care should be taken (especially when using peripheral boards) to ensure that no more than 500mA is drawn.

PS/2 Port

The 6-pin mini-DIN connector can accommodate a PS/2 mouse or keyboard. Most PS/2 devices can operate from a 3.3V supply, but older devices may require a 5VDC supply. A three-pin jumper on the Nexys2 board immediately adjacent to the PS/2 connector selects whether regulated 3.3V or the main input power bus voltage (VU) is supplied to the PS/2 connector. To send 5V to the PS/2 connector, set the PS2 power jumper to Vswt (the main input power bus), and ensure the board is powered from USB or a 5VDC wall-plug supply. To send 3.3V to the connector, set the jumper to 3.3V.

Both the mouse and keyboard use a two-wire serial bus (clock and data) to communicate with a host device. Both use 11-bit words that include a start, stop and odd parity bit, but the data packets are organized differently, and the keyboard interface allows bi-directional data transfers (so the host device can illuminate state LEDs on the keyboard). Bus timings are shown in the figure. The clock and data signals are only driven when data transfers occur, and otherwise they are held in the “idle” state at logic ‘1’. The timings define signal requirements for mouse-to-host communications and bi-directional keyboard communications. A PS/2 interface circuit can be implemented in the FPGA to create a keyboard or mouse interface.

Both the mouse and keyboard use a two-wire serial bus (clock and data) to communicate with a host device. Both use 11-bit words that include a start, stop and odd parity bit, but the data packets are organized differently, and the keyboard interface allows bi-directional data transfers (so the host device can illuminate state LEDs on the keyboard). Bus timings are shown in the figure. The clock and data signals are only driven when data transfers occur, and otherwise they are held in the “idle” state at logic ‘1’. The timings define signal requirements for mouse-to-host communications and bi-directional keyboard communications. A PS/2 interface circuit can be implemented in the FPGA to create a keyboard or mouse interface.

Keyboard

The keyboard uses open-collector drivers so the keyboard or an attached host device can drive the two-wire bus (if the host device will not send data to the keyboard, then the host can use input-only ports).

PS2-style keyboards use scan codes to communicate key press data. Each key is assigned a code that is sent whenever the key is pressed; if the key is held down, the scan code will be sent repeatedly about once every 100ms. When a key is released, a “F0” key-up code is sent, followed by the scan code of the released key. If a key can be “shifted” to produce a new character (like a capital letter), then a shift character is sent in addition to the scan code, and the host must determine which ASCII character to use. Some keys, called extended keys, send an “E0” ahead of the scan code (and they may send more than one scan code). When an extended key is released, an “E0 F0” key-up code is sent, followed by the scan code. Scan codes for most keys are shown in the figure. A host device can also send data to the keyboard. Below is a short list of some common commands a host might send.

- ED Set Num Lock, Caps Lock, and Scroll Lock LEDs. Keyboard returns “FA” after receiving “ED”, then host sends a byte to set LED status: Bit 0 sets Scroll Lock; bit 1 sets Num Lock; and Bit 2 sets Caps lock. Bits 3 to 7 are ignored.

- EE Echo (test). Keyboard returns “EE” after receiving “EE”.

- F3 Set scan code repeat rate. Keyboard returns “F3” on receiving “FA”, then host sends second byte to set the repeat rate.

- FE Resend. “FE” directs keyboard to re-send most recent scan code.

- FF Reset. Resets the keyboard.

The keyboard can send data to the host only when both the data and clock lines are high (or idle). Since the host is the “bus master”, the keyboard must check to see whether the host is sending data before driving the bus. To facilitate this, the clock line is used as a “clear to send” signal. If the host pulls the clock line low, the keyboard must not send any data until the clock is released. The keyboard sends data to the host in 11-bit words that contain a ‘0’ start bit, followed by 8-bits of scan code (LSB first), followed by an odd parity bit and terminated with a ‘1’ stop bit. The keyboard generates 11 clock transitions (at around 20 - 30KHz) when the data is sent, and data is valid on the falling edge of the clock.

Scan codes for most PS/2 keys are shown in the figure below.

Mouse

The mouse outputs a clock and data signal when it is moved; otherwise, these signals remain at logic ‘1’. Each time the mouse is moved, three 11-bit words are sent from the mouse to the host device. Each of the 11-bit words contains a ‘0’ start bit, followed by 8 bits of data (LSB first), followed by an odd parity bit, and terminated with a ‘1’ stop bit. Thus, each data transmission contains 33 bits, where bits 0, 11, and 22 are ‘0’ start bits, and bits 10, 21, and 33 are ‘1’ stop bits. The three 8-bit data fields contain movement data as shown in the figure above. Data is valid at the falling edge of the clock, and the clock period is 20 to 30KHz.

The mouse assumes a relative coordinate system wherein moving the mouse to the right generates a positive number in the X field, and moving to the left generates a negative number. Likewise, moving the mouse up generates a positive number in the Y field, and moving down represents a negative number (the XS and YS bits in the status byte are the sign bits – a ‘1’ indicates a negative number). The magnitude of the X and Y numbers represent the rate of mouse movement – the larger the number, the faster the mouse is moving (the XV and YV bits in the status byte are movement overflow indicators – a ‘1’ means overflow has occurred). If the mouse moves continuously, the 33-bit transmissions are repeated every 50ms or so. The L and R fields in the status byte indicate Left and Right button presses (a ‘1’ indicates the button is being pressed).

VGA Port

The Nexys2 board uses 10 FPGA signals to create a VGA port with 8-bit color and the two standard sync signals (HS – Horizontal Sync, and VS – Vertical Sync). The color signals use resistor-divider circuits that work in conjunction with the 75-ohm termination resistance of the VGA display to create eight signal levels on the red and green VGA signals, and four on blue (the human eye is less sensitive to blue levels). This circuit, shown in figure 13, produces video color signals that proceed in equal increments between 0V (fully off) and 0.7V (fully on). Using this circuit, 256 different colors can be displayed, one for each unique 8-bit pattern. A video controller circuit must be created in the FPGA to drive the sync and color signals with the correct timing in order to produce a working display system.

The Nexys2 board uses 10 FPGA signals to create a VGA port with 8-bit color and the two standard sync signals (HS – Horizontal Sync, and VS – Vertical Sync). The color signals use resistor-divider circuits that work in conjunction with the 75-ohm termination resistance of the VGA display to create eight signal levels on the red and green VGA signals, and four on blue (the human eye is less sensitive to blue levels). This circuit, shown in figure 13, produces video color signals that proceed in equal increments between 0V (fully off) and 0.7V (fully on). Using this circuit, 256 different colors can be displayed, one for each unique 8-bit pattern. A video controller circuit must be created in the FPGA to drive the sync and color signals with the correct timing in order to produce a working display system.

VGA Timing System

VGA signal timings are specified, published, copyrighted and sold by the VESA organization (www.vesa.org). The following VGA system timing information is provided as an example of how a VGA monitor might be driven in 640 by 480 mode. For more precise information, or for information on other VGA frequencies, refer to documentation available at the VESA website.

CRT-based VGA displays use amplitude-modulated moving electron beams (or cathode rays) to display information on a phosphor-coated screen. LCD displays use an array of switches that can impose a voltage across a small amount of liquid crystal, thereby changing light permittivity through the crystal on a pixel-by-pixel basis.  Although the following description is limited to CRT displays, LCD displays have evolved to use the same signal timings as CRT displays (so the “signals” discussion below pertains to both CRTs and LCDs). Color CRT displays use three electron beams (one for red, one for blue, and one for green) to energize the phosphor that coats the inner side of the display end of a cathode ray tube (see illustration). Electron beams emanate from “electron guns” which are finely-pointed heated cathodes placed in close proximity to a positively charged annular plate called a “grid”. The electrostatic force imposed by the grid pulls rays of energized electrons from the cathodes, and those rays are fed by the current that flows into the cathodes. These particle rays are initially accelerated towards the grid, but they soon fall under the influence of the much larger electrostatic force that results from the entire phosphor-coated display surface of the CRT being charged to 20kV (or more). The rays are focused to a fine beam as they pass through the center of the grids, and then they accelerate to impact on the phosphor-coated display surface. The phosphor surface glows brightly at the impact point, and it continues to glow for several hundred microseconds after the beam is removed. The larger the current fed into the cathode, the brighter the phosphor will glow.

Although the following description is limited to CRT displays, LCD displays have evolved to use the same signal timings as CRT displays (so the “signals” discussion below pertains to both CRTs and LCDs). Color CRT displays use three electron beams (one for red, one for blue, and one for green) to energize the phosphor that coats the inner side of the display end of a cathode ray tube (see illustration). Electron beams emanate from “electron guns” which are finely-pointed heated cathodes placed in close proximity to a positively charged annular plate called a “grid”. The electrostatic force imposed by the grid pulls rays of energized electrons from the cathodes, and those rays are fed by the current that flows into the cathodes. These particle rays are initially accelerated towards the grid, but they soon fall under the influence of the much larger electrostatic force that results from the entire phosphor-coated display surface of the CRT being charged to 20kV (or more). The rays are focused to a fine beam as they pass through the center of the grids, and then they accelerate to impact on the phosphor-coated display surface. The phosphor surface glows brightly at the impact point, and it continues to glow for several hundred microseconds after the beam is removed. The larger the current fed into the cathode, the brighter the phosphor will glow.

Between the grid and the display surface, the beam passes through the neck of the CRT where two coils of wire produce orthogonal electromagnetic fields. Because cathode rays are composed of charged particles (electrons), they can be deflected by these magnetic fields. Current waveforms are passed through the coils to produce magnetic fields that interact with the cathode rays and cause them to transverse the display surface in a “raster” pattern, horizontally from left to right and vertically from top to bottom. As the cathode ray moves over the surface of the display, the current sent to the electron guns can be increased or decreased to change the brightness of the display at the cathode ray impact point.

Information is only displayed when the beam is moving in the “forward” direction (left to right and top to bottom), and not during the time the beam is reset back to the left or top edge of the display. Much of the potential display time is therefore lost in “blanking” periods when the beam is reset and stabilized to begin a new horizontal or vertical display pass. The size of the beams, the frequency at which the beam can be traced across the display, and the frequency at which the electron beam can be modulated determine the display resolution.  Modern VGA displays can accommodate different resolutions, and a VGA controller circuit dictates the resolution by producing timing signals to control the raster patterns. The controller must produce synchronizing pulses at 3.3V (or 5V) to set the frequency at which current flows through the deflection coils, and it must ensure that video data is applied to the electron guns at the correct time. Raster video displays define a number of “rows” that corresponds to the number of horizontal passes the cathode makes over the display area, and a number of “columns” that corresponds to an area on each row that is assigned to one “picture element” or pixel. Typical displays use from 240 to 1200 rows and from 320 to 1600 columns. The overall size of a display and the number of rows and columns determines the size of each pixel.

Modern VGA displays can accommodate different resolutions, and a VGA controller circuit dictates the resolution by producing timing signals to control the raster patterns. The controller must produce synchronizing pulses at 3.3V (or 5V) to set the frequency at which current flows through the deflection coils, and it must ensure that video data is applied to the electron guns at the correct time. Raster video displays define a number of “rows” that corresponds to the number of horizontal passes the cathode makes over the display area, and a number of “columns” that corresponds to an area on each row that is assigned to one “picture element” or pixel. Typical displays use from 240 to 1200 rows and from 320 to 1600 columns. The overall size of a display and the number of rows and columns determines the size of each pixel.

Video data typically comes from a video refresh memory, with one or more bytes assigned to each pixel location (the Nexys2 uses three bits per pixel). The controller must index into video memory as the beams move across the display, and retrieve and apply video data to the display at precisely the time the electron beam is moving across a given pixel.

A VGA controller circuit must generate the HS and VS timings signals and coordinate the delivery of video data based on the pixel clock. The pixel clock defines the time available to display one pixel of information. The VS signal defines the “refresh” frequency of the display, or the frequency at which all information on the display is redrawn. The minimum refresh frequency is a function of the display’s phosphor and electron beam intensity, with practical refresh frequencies falling in the 50Hz to 120Hz range. The number of lines to be displayed at a given refresh frequency defines the horizontal “retrace” frequency. For a 640-pixel by 480-row display using a 25MHz pixel clock and 60 +/-1Hz refresh, the signal timings shown in the table at right can be derived. Timings for sync pulse width and front and back porch intervals (porch intervals are the pre- and post-sync pulse times during which information cannot be displayed) are based on observations taken from actual VGA displays.

A VGA controller circuit must generate the HS and VS timings signals and coordinate the delivery of video data based on the pixel clock. The pixel clock defines the time available to display one pixel of information. The VS signal defines the “refresh” frequency of the display, or the frequency at which all information on the display is redrawn. The minimum refresh frequency is a function of the display’s phosphor and electron beam intensity, with practical refresh frequencies falling in the 50Hz to 120Hz range. The number of lines to be displayed at a given refresh frequency defines the horizontal “retrace” frequency. For a 640-pixel by 480-row display using a 25MHz pixel clock and 60 +/-1Hz refresh, the signal timings shown in the table at right can be derived. Timings for sync pulse width and front and back porch intervals (porch intervals are the pre- and post-sync pulse times during which information cannot be displayed) are based on observations taken from actual VGA displays.

A VGA controller circuit decodes the output of a horizontal-sync counter driven by the pixel clock to generate HS signal timings. This counter can be used to locate any pixel location on a given row. Likewise, the output of a vertical-sync counter that increments with each HS pulse can be used to generate VS signal timings, and this counter can be used to locate any given row. These two continually running counters can be used to form an address into video RAM. No time relationship between the onset of the HS pulse and the onset of the VS pulse is specified, so the designer can arrange the counters to easily form video RAM addresses, or to minimize decoding logic for sync pulse generation.

Serial Port

The Nexys2 contains a two-wire serial port based on an ST Microelectronics ST3232 voltage converter. The ST3232 converts the signal levels used by RS-232 communications (-12 to -3 for a logic ‘1’ and 12V to 3V for a logic ‘0’) to the 3.3V signals used by the FPGA. Since only two signals are connected (RXD and TXD), an FPGA-based serial port controller can only use software hand-shaking protocols (XON/XOFF). The Nexys2 serial port is useful for many applications, and in particular for debugging and working with Xilinx’s MicroBlaze embedded processor.

The two devices connected to either end of a serial cable are known as the Data Terminal Equipment (DTE) and the Data Communications Equipment (DCE). The DCE was originally conceived to be a modem, but now many devices connect to a computer as a DCE.  A DTE “source” device uses a male DB-9 connector, and a DCE “peripheral” device uses a female DB-9 connector. Two DTE devices can be connected via a serial cable only if lines two and three (RXD and TXD) are crossed, producing what is known as a null modem cable. A DTE and DCE device can be connected with a straight-through cable. The Nexys2 is configured as a DCE device, with the assumption it will most typically be connected to a DTE device like a computer.

A DTE “source” device uses a male DB-9 connector, and a DCE “peripheral” device uses a female DB-9 connector. Two DTE devices can be connected via a serial cable only if lines two and three (RXD and TXD) are crossed, producing what is known as a null modem cable. A DTE and DCE device can be connected with a straight-through cable. The Nexys2 is configured as a DCE device, with the assumption it will most typically be connected to a DTE device like a computer.

Memory

The Nexys2 board has external RAM and ROM devices. The external RAM is a 128Mbit Micron M45W8MW16 Cellular RAM pseudo-static DRAM device organized as 8Mbytes x 16bits. It can operate as a typical asynchronous SRAM with read and write cycle times of 70ns, or as a synchronous memory with an 80MHz bus. When operated as an asynchronous SRAM, the Cellular RAM automatically refreshes its internal DRAM arrays, allowing for a simplified memory controller design (similar to any SRAM) in the FPGA. When operated in synchronous mode, continuous transfers of up to 80MHz are possible.

The external ROM is a 128Mbit Intel TE28F128J3D75-110 StrataFlash device organized as 8Mbytes x 16bits. Internally, it contains 128 blocks that can be individually erased, and it supports 110ns read cycle times, with 25ns page-mode reads within blocks. It has an internal 32-byte write buffer that can be written with 70ns cycle times, and the 32-byte buffer can be transferred to the Flash array in 218us (typical).

Both devices share a common 16-bit data bus and 24-bit address bus. The Cellular RAM is byte addressable using the upper-byte and lower-byte signals (MT-UB and MT-LB), but the StrataFlash is configured for 16 byte operations only (it is not byte addressable). The output enable (OE) and write enable (WE) signals are shared by both devices, but each device has individual chip enable (CE) signals. Additionally, the Cellular RAM has clock (MT-CLK), wait (MT-WAIT), address valid (MT-ADV) and control register enable (MT_CRE) signals available to the FPGA for use with synchronous transfers, and the StrataFlash has Reset (RP#) and status (STS) signals routed to the FPGA.

VDHL source code is available in a reference design posted on the Digilent website to illustrate the use of these devices. A base system builder file is also available for using these devices with Xilinx’s EDK tool and MicroBlaze processor core, both available from Xilinx. Complete information is available for both devices from the manufacturer websites.

| Memory Address and Data Bus Pin Assignments | |||||||||

| Address signals | Data signals | ||||||||

| ADDR0: | NA | ADDR8: | H6 | ADDR16: | M5 | DATA0: | L1 | DATA8: | L3 |

| ADDR1: | J1 | ADDR9: | F1 | ADDR17: | E2 | DATA1: | L4 | DATA9: | L5 |

| ADDR2: | J2 | ADDR10: | G3 | ADDR18: | C2 | DATA2: | L6 | DATA10: | M3 |

| ADDR3: | H4 | ADDR11: | G6 | ADDR19: | C1 | DATA3: | M4 | DATA11: | M6 |

| ADDR4: | H1 | ADDR12: | G5 | ADDR20: | D2 | DATA4: | N5 | DATA12: | L2 |

| ADDR5: | H2 | ADDR13: | G4 | ADDR21: | K3 | DATA5: | P1 | DATA13: | N4 |

| ADDR6: | J5 | ADDR14: | F2 | ADDR22: | D1 | DATA6: | P2 | DATA14: | R3 |

| ADDR7: | H3 | ADDR15: | E1 | ADDR23: | K6 | DATA7: | R2 | DATA15: | T1 |

Peripheral Connectors

The Nexys2 board provides four two-row 6-pin Pmod connectors that together can accommodate up to 8 Pmods. The four 12-pin connectors each have 8 data signals, two GND pins, and two Vdd pins. All data signals include short circuit protection resistors and ESD protection Diodes. A jumper block adjacent to each Pmod connector can connect the Pmod’s Vdd signal to the Nexys2 board’s 3.3V supply or to the input power bus (VU). If the jumper is set to VU and USB power is driving the main power bus, care should be taken to ensure no more than 200mA is consumed by the Pmod. Further, if the jumper is set to VU, a voltage source connected to the Pmod can drive the main power bus of the Nexys2 board, so care should be taken to avoid connecting conflicting power supplies.

The Pmod connectors are labeled JA (nearest the power jack), JB, JC, and JD (nearest the expansion connector). Pinouts for the Pmod connectors are provided in the table below.

More than 30 low-cost are available for attachment to these connectors. Pmods can either be attached directly, or by using a small cable. Available Pmods include A/D and D/A converters, motor drivers, speaker amplifiers, distance measuring devices, etc. Please see www.digilentinc.com for more information.

| Nexys2 Pmod Connector Pin Assignments | |||||||||||||||

| Pmod JA | Pmod JB | Pmod JC | Pmod JD | ||||||||||||

| JA1: | L15 | JA7: | K13 | JB1: | M13 | JB7: | P17 | JC1: | G15 | JC7: | H15 | JD1: | J13 | JD7: | K14 |

| JA2: | K12 | JA8: | L16 | JB2: | R18 | JB8: | R16 | JC2: | J16 | JC8: | F14 | JD2: | M18 | JD8: | K15 |

| JA3: | L17 | JA9: | M14 | JB3: | R15 | JB9: | T18 | JC3: | G13 | JC9: | G16 | JD3: | N18 | JD9: | J15 |

| JA4: | M15 | JA10: | M16 | JB4: | T17 | JB10: | U18 | JC4: | H16 | JC10: | J12 | JD4:; | P18 | JD10: | J14 |

Expansion connector

The Nexys2 board includes a Hirose FX-2 high-density 100 pin connector that is suitable for driving peripheral boards with signal rates in excess of 100 MHz. Many connector signals are routed to the FPGA as differential pairs, and 47 connector pins are tied to ground, resulting in a very low-noise connection system. The self-aligning Hirose FX-2 connector can be used for board-to-board connections or board-to-cable connections using the mating Hirose FX2-100S-1.27 available from many catalog distributors and directly from Digilent.

All signals routed from the FPGA to the FX-2 connector include 75-ohm series resistors. The table on the right shows all signal connections between the FX-2 connector and the FPGA. Signals without corresponding entries in the FPGA column are not directly connected to the FPGA.

| Hirose FX2 Connector Pin Assignments | |||||

| J1A | Name | FPGA | J1B | Name | FPGA |

| 1 | VCC3V3 | 1 | SHIELD | ||

| 2 | VCC3V3 | 2 | GND | ||

| 3 | TMS | 3 | TDO-ROM | ||

| 4 | JTSEL | 4 | TCK | A17 | |

| 5 | TDO-FX2 | 5 | GND | ||

| 6 | FX2-IO1 | 6 | GND | ||

| 7 | FX2-IO2 | 7 | GND | ||

| 8 | FX2-IO3 | 8 | GND | ||

| 9 | FX2-IO4 | 9 | GND | ||

| 10 | FX2-IO5 | 10 | GND | ||

| 11 | FX2-IO6 | 11 | GND | ||

| 12 | FX2-IO7 | 12 | GND | ||

| 13 | FX2-IO8 | 13 | GND | ||

| 14 | FX2-IO9 | 14 | GND | ||

| 15 | FX2-IO10 | 15 | GND | ||

| 16 | FX2-IO11 | 16 | GND | ||

| 17 | FX2-IO12 | 17 | GND | ||

| 18 | FX2-IO13 | 18 | GND | ||

| 19 | FX2-IO14 | 19 | GND | ||

| 20 | FX2-IO15 | 20 | GND | ||

| 21 | FX2-IO16 | 21 | GND | ||

| 22 | FX2-IO17 | 22 | GND | ||

| 23 | FX2-IO18 | 23 | GND | ||

| 24 | FX2-IO19 | 24 | GND | ||

| 25 | FX2-IO20 | 25 | GND | ||

| 26 | FX2-IO21 | 26 | GND | ||

| 27 | FX2-IO22 | 27 | GND | ||

| 28 | FX2-IO23 | 28 | GND | ||

| 29 | FX2-IO24 | 29 | GND | ||

| 30 | FX2-IO25 | 30 | GND | ||

| 31 | FX2-IO26 | 31 | GND | ||

| 32 | FX2-IO27 | 32 | GND | ||

| 33 | FX2-IO28 | 33 | GND | ||

| 34 | FX2-IO29 | 34 | GND | ||

| 35 | FX2-IO30 | 35 | GND | ||

| 36 | FX2-IO31 | 36 | GND | ||

| 37 | FX2-IO32 | 37 | GND | ||

| 38 | FX2-IO33 | 38 | GND | ||

| 39 | FX2-IO34 | 39 | GND | ||

| 40 | FX2-IO35 | 40 | GND | ||

| 41 | FX2-IO36 | 41 | GND | ||

| 42 | FX2-IO37 | 42 | GND | ||

| 43 | FX2-IO38 | 43 | GND | ||

| 44 | FX2-IO39 | 44 | GND | ||

| 45 | FX2-IO40 | 45 | GND | ||

| 46 | GND | 46 | FX2-CLKIN | B9 | |

| 47 | FX2-CLKOUT | D9 | 47 | GND | |

| 48 | GND | 48 | FX2-CLKIO | M9 | |

| 49 | VCCFX2 | 49 | VCCFX2 | ||

| 50 | VCCFX2 | 50 | SHIELD | ||

Built in Self Test

A demonstration configuration is loaded into the Platform Flash ROM on the Nexys2 board during manufacturing. This demo, also available on the resource CD and on the Digilent website, can serve as a board verification test since it interacts with all devices and ports on the board. To configure the FPGA from a bit file stored in Platform Flash, set the Mode Jumper to Slave Serial and cycle power or press the FPGA reset button.

The self-test checks the on-board memories, and then connects the switches to the LEDs, the buttons and PS/2 keyboard (if attached) to the seven-segment display, and a VGA monitor (if attached) will show a color pattern. If the on-board memories pass test, “PASS” will be displayed on the seven-segment display (otherwise, “FAIL”). After the memory test, the buttons and switches will drive the LEDs and seven-segment display, so that all user I/O devices can be manually checked.

If the self test is not resident in the Platform Flash ROM, it can be programmed into the FPGA or reloaded into the ROM using the Adept programming software.

All Nexys2 boards are 100% tested during the manufacturing process. If any device on the Nexys2 board fails test or is not responding properly, it is likely that damage occurred during transport or during use. Typical damage includes stressed solder joints, or contaminants in switches and buttons resulting in intermittent failures. Stressed solder joints can be repaired by reheating and reflowing solder, and contaminants can be cleaned with off-the-shelf electronics cleaning products. If a board fails test within the warranty period, it will be replaced at no cost. If a board fails test outside of the warranty period and cannot be easily repaired, Digilent can repair the board for a fee. Contact Digilent for more details.